Since its inception,

digital inkjet technology has revolutionized the printing industry. This

technology delivers high-resolution image outputs on various substrates in an

efficient and flexible manner. At the core of inkjet printing lies the

printhead design, which directly impacts print quality, production efficiency,

and overall costs.

Although the

principle of printheads—jetting ink onto substrates—appears straightforward,

the mechanisms for generating ink droplets differ greatly among types. The two

primary types of printheads available in the market are thermal bubble

printheads and piezoelectric printheads, each

excelling in different applications and technical characteristics. Let’s delve

into these printheads to give you a comprehensive understanding of the core

technology in inkjet printing.

Basic

Principles of Inkjet Technology

The essence of

digital inkjet technology lies in converting liquid ink into microscopic

droplets and accurately jetting them onto a substrate’s surface to form desired

text or images. These droplets, typically just a few microns in diameter, are

digitally controlled to ensure precision and flexibility.

Key Elements of

Inkjet Technology:

Droplet Formation: The printhead generates tiny ink droplets, with their size and shape directly affecting print quality.

Precise Positioning: Computer-controlled systems synchronize printhead movements with ink release for exact image placement.

Versatile Substrate Compatibility: The technology supports a wide range of materials, including paper, plastics, metals, and fabrics, catering to diverse applications.

The way printheads

manage droplet generation defines the primary difference between thermal bubble

and piezoelectric technologies.

Thermal Bubble

Printheads: A Deep Dive into Technology and Applications

How It Works: From

Heat to Droplets

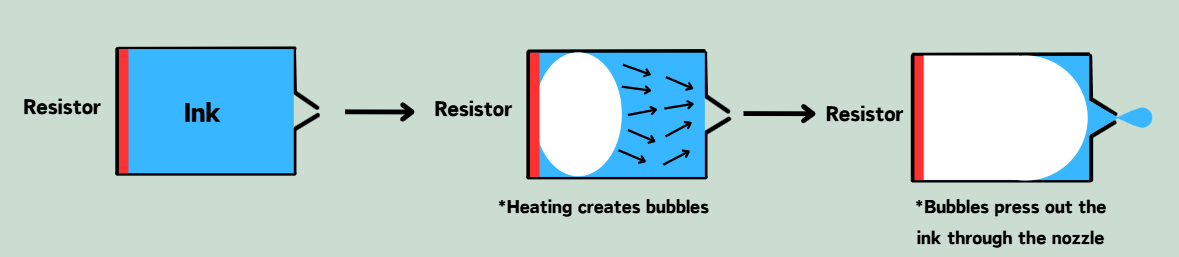

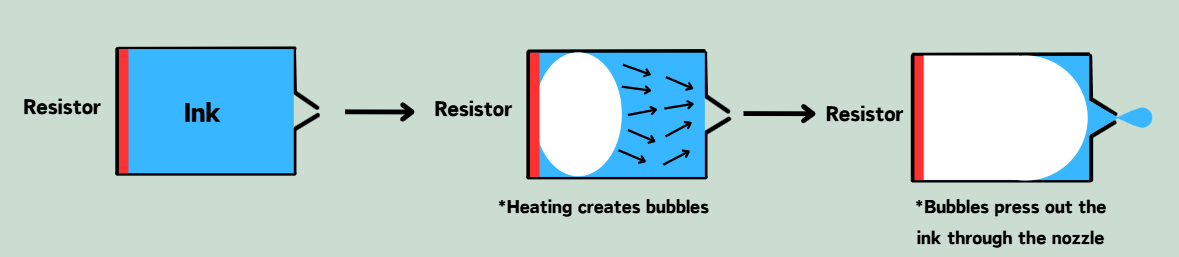

Thermal bubble

printheads (Thermal Inkjet, or TIJ) rely on heating elements and the thermal

expansion of ink. When ink enters the printhead’s chamber, a heating element

rapidly heats it to its boiling point (around 300°C). This high temperature

creates tiny vapor bubbles that expand and generate pressure to eject the ink

droplet onto the substrate. As the bubble collapses, the pressure dissipates,

and the chamber refills with ink, completing the cycle.

Thermal bubble

printhead design:

Technical Features

and Advantages

Technical Features

and Advantages

1.Simple

and Efficient Design:

Thermal bubble printheads have a relatively straightforward structure

consisting of miniature heating elements and ink channels. This simplicity

makes them cost-effective and suitable for mass production, particularly for

consumer and small-scale commercial printers.

2.High-Resolution

Output:

By controlling the heating element’s pulse voltage, these printheads produce

ink droplets as small as a few picoliters, enabling sharp images and detailed

text. They are ideal for high-resolution document printing and color image

reproduction.

Limitations and

Challenges

1.Component

Wear and Shorter Lifespan:

Prolonged high-temperature operation wears down heating elements, leading to

shorter printhead lifespans and increased replacement costs.

2.Ink

Limitations:

Thermal printheads are restricted to water-based inks since solvent-based or

UV-curable inks may degrade or damage the printhead under high temperatures.

3.Heat

Impact on Color Consistency:

High temperatures may cause slight color deviations, posing challenges for

applications requiring consistent color fidelity.

Common Applications

Thermal bubble printheads

are widely used in home or small office printers (e.g., HP, Canon) and

lightweight commercial applications such as label printing. Their affordability

and economic efficiency make them dominant in the entry-level market.

Piezoelectric

Printheads: Precision for Industrial Applications

How It Works:

Voltage-Driven Deformation Technology

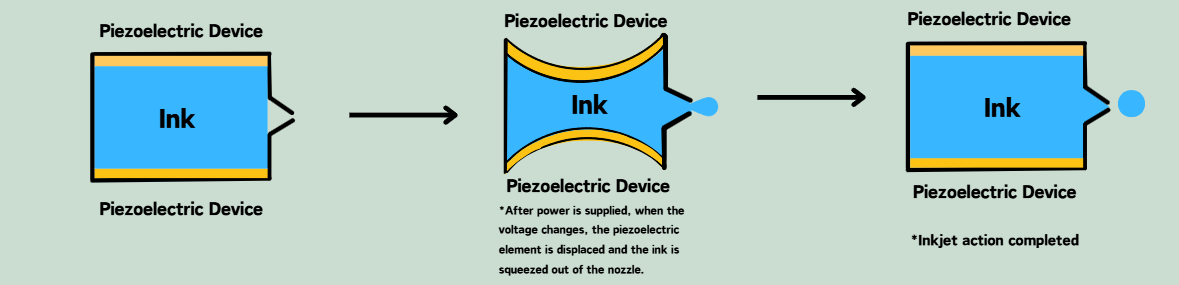

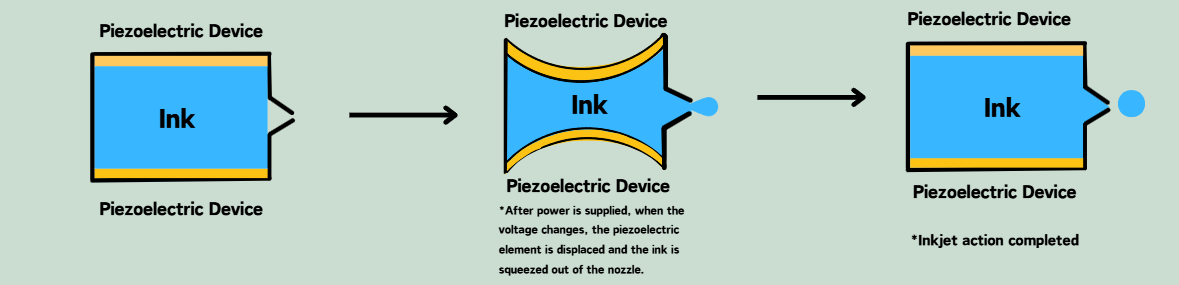

Piezoelectric

printheads utilize the piezoelectric effect, where piezoelectric materials

deform when subjected to an electric voltage. Within the printhead’s chamber,

piezoelectric elements (such as piezoelectric ceramics) compress the ink

chamber through deformation, ejecting ink droplets precisely. Unlike thermal

bubble printheads, piezoelectric ones do not rely on heat but solely on

mechanical pressure to generate droplets.

Piezoelectric

printheads design:

Technical Features

and Advantages

Technical Features

and Advantages

1.Broad

Ink Compatibility:

Piezoelectric printheads can handle a variety of inks, including water-based,

solvent-based, UV-curable, and even high-viscosity or pigment-rich inks, making

them suitable for a wide range of applications.

2.High

Precision and Stability:

These printheads control droplet size and shape for ultra-high-resolution

output. Additionally, their non-thermal operation ensures exceptional stability

and longer lifespan compared to thermal printheads.

3.Low

Wear and Tear:

With minimal consumable parts, piezoelectric printheads are designed for

extended production cycles, making them ideal for industrial-scale operations.

Challenges and

Drawbacks

1.High

Manufacturing and Maintenance Costs:

Due to their intricate design, piezoelectric printheads have higher production

costs, which may present a barrier for smaller businesses.

2.Complex

Operation Requirements:

Their precision structure demands advanced technical expertise for operation

and maintenance, requiring professional training to achieve optimal

performance.

Advanced

Application Scenarios

Piezoelectric

printheads are extensively used in industrial and professional printing

sectors, such as:

Textile Printing: High-quality designs on fabrics for fashion and home décor.

Packaging Printing: Sharp text and graphics on materials like plastic films and metal foils.

Electronics Industry: Marking on components or printing micro-electronic circuits.

Medical and Biotechnology: Precise dispensing of bio-inks in 3D bioprinting for cell and tissue engineering.

Choosing

Between Piezoelectric and Thermal Bubble Technologies

Both printhead

technologies have their strengths. Selecting the right one depends on the

following considerations:

Cost Sensitivity: Thermal bubble technology is ideal for cost-conscious users, while piezoelectric printheads suit industrial-scale operations focusing on long-term benefits.

Ink Versatility: Piezoelectric printheads offer unmatched flexibility, supporting diverse applications.

Product Lifespan: Piezoelectric printheads, with their non-thermal design, outlast their thermal counterparts.

Comparison of

Thermal Bubble and Piezoelectric Printheads

|

Feature

|

Thermal Bubble

|

Piezoelectric

|

|

Cost

|

Low, ideal for small-scale use

|

High, suitable for industrial use

|

|

Lifespan

|

Short, requires frequent replacement

|

Long, highly durable

|

|

Ink Compatibility

|

Limited to water-based inks

|

Compatible with various ink types

|

|

Application

|

Home and small-scale commercial

|

Industrial-scale printing

|

Future Trends

in Printhead Technology

Higher Speed and

Precision

Future printhead

designs will emphasize faster jetting frequencies and smaller droplet sizes to

enhance printing speed and resolution. Integrating AI technologies will further

optimize inkjet processes through automated calibration and precision control.

Sustainability and

Energy Efficiency

Eco-friendly inks,

such as water-based UV inks, are becoming mainstream. Printhead designs are

also evolving toward lower energy consumption and greater efficiency.

Cross-Industry

Applications

Inkjet technology is

expanding beyond printing to fields like healthcare, biotechnology, and food

packaging. For instance, 3D bioprinting uses inkjet-inspired printheads to

dispense bio-inks for cell and tissue engineering.

Conclusion

The success of

digital inkjet technology relies on innovative printhead designs and

technological advancements. Whether it’s the cost-effective thermal bubble

printheads or the versatile, high-precision piezoelectric printheads, each has

its irreplaceable role in their respective applications.

Choosing the right

printhead technology involves a balanced assessment of cost, application,

material compatibility, and production scale. For inquiries about ink or inkjet

technology, visit

Chromo

Ink.

We are committed to delivering premium ink products and professional solutions

to elevate your printing business to the next level!