The print industry has never been so challenging in the late years, from traditional to digital, all optimized towards small-volume, large-variety , wider color gamut, functionality, higher speed, environmental friendly. Nevertheless, broad application levels and good quality are still the major concern among all. Driven by the rising global environmental awareness, a joint alliance of KYMC, TSLC & RPC, has launched first C.I. LED UV flexo printing machine, targeting at zero air pollution in printing, energy saving and green printing as utmost aim.

Energy Saving, Green Printing

Printing brings colors and convenience to human lives. Most of printing requires organic solvents to fit un-permeable substrates such like plastic films, since then the VOCs and the working environment safety have been an existing concern to all. Settlement of air extraction equipment, for example, although is helpful but still not a long term resolution at all. RPC, therefore, deepened researches on the major printing resources, developed water-based inks to get rid of annoying ventilation issue at once. But water based inks meets another barrier unable to surpass- shrink wrapping film cannot tolerate such high temperature for dryness!

Up to recent years, solvent-based inks are the solution for un-permeable substrates, due to its high temperatures (>50°C) toleration. In order to challenging such property, RPC has developed LED UV flexo ink series to replace conventional solvent type. LED UV ink is good option for not containing volatile solvents and no odors after curing. It is equipped with LED lights provided by TSLC. LED UV lights are cold light sources. It’s cost saving, less OZONE emission, life span could reach 30,000 hours.

Asia`s first C.I. LED UV flexographic printing machine

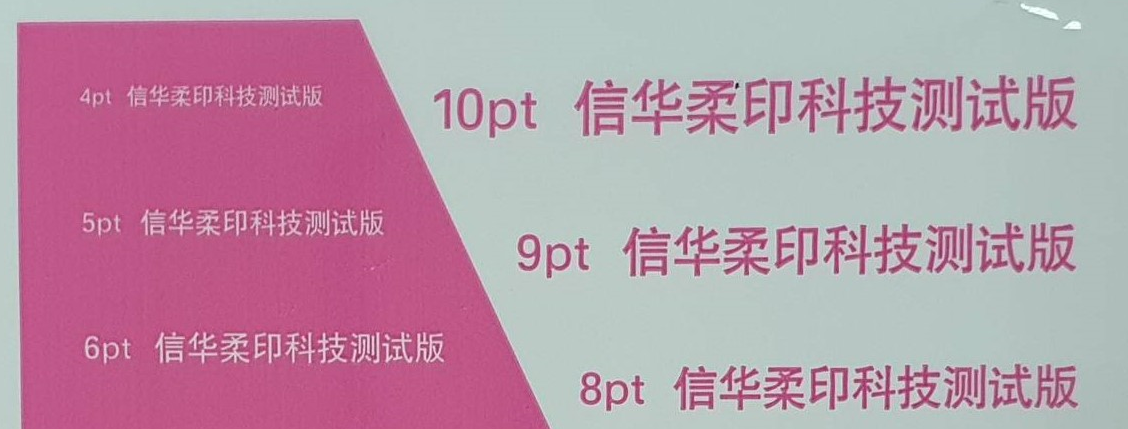

Despite of the fact that many still adopts narrow-format flexographic printing , RPC, KYMC & TSLC, together intend to shift from Red to Blue ocean, by developing this “wide-format LED UV CI flexographic printing system”, we intend to agglomerate all printing effects at once: high-quality, environmental friendly, high-speed (up to 350m per minute), small fonts clearly displayed. (ref.: Figure 1)

Figure 1

For existing solvent ink holder, LED UV ink & Solvent ink printing could create outstanding effects to graphic design too. (Ref.: Figure 2)

Figure 2: (Orange part is solvent, black is LED UV Flexo ink)

Ink Performance Comparison

Ink Type | OPP | PET | CPP | Shrink film | NO VOCs

| Low Odor | Low Flammability |

LED UV | O | O | O | O | O | O | O |

Water based | O | O | O | X | O | O | O |

Solvent based | O | O | O | O | X | X | X |

O:Good X:Poor

RPC, inherited from CF Group, which started colorants industry a decade ago, has continuously endeavored to develop a fine colorant industry since then. Through the establishment of "Colorant application R&D Center" and an "Ink Research Center", plus recognition by awards like “National Nano Industry Technology Elite” and “SMEs Innovative research” , “outstanding SBIR R&D alliance” . RPC has "pigment dyeing" as new project, aiming at reducing pollution from colorant manufacturing and increase the durability of products to reach environmental protection demands.