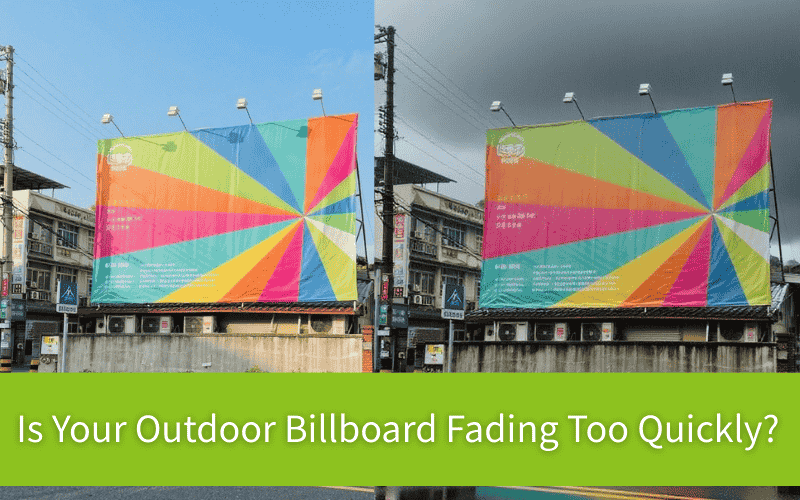

Outdoor billboards are expected to maintain their visual appeal for months or even years. Any noticeable fading or quality decline directly impacts the advertiser’s brand image and return on investment. That’s why billboard inks must not only deliver excellent UV resistance but also maintain color stability under extreme weather conditions. While these professional-grade inks may cost more upfront, they create significant long-term value for customers.

Environmental Threat | Impact on Ink | Customer Expectation | Business Consideration |

|---|---|---|---|

| UV Radiation | Continuous exposure damages color molecule structures | Longer usage cycle | Lower overall cost |

| Temperature Fluctuations | Daily expansion and contraction of materials | Consistent visual quality | Brand consistency |

| High Humidity | Weakens ink stability and adhesion | Higher product quality standards | Meeting strict requirements |

| Air Pollution | Pollutants accelerate material aging | Compliance with environmental laws | Meeting market entry standards |

The real service life of outdoor prints depends on multiple factors. Understanding these variables is crucial for choosing the right printing solution.

The core of weather-resistant ink lies in the use of high lightfast pigments. For example, LED UV-curable ink, premium-grade lightfast pigments combined with advanced formulation technology can deliver outstanding performance even in harsh environments. While ink quality is only one factor influencing weather resistance, it remains the main reason colors do not fade.

Different substrates directly affect ink adhesion and long-term weather resistance. Pairing high-quality outdoor substrates with fade-resistant ink delivers the best performance. Surface treatment, thickness, and material properties all play a role. Common billboard substrates include PVC, acrylic, and fabric banners. Selecting the right substrate, along with the right ink, ensures vivid, long-lasting visuals even in challenging environments.

When selecting billboard ink, it’s important to evaluate multiple criteria to ensure long-lasting performance in tough outdoor environments:

After 864 hours of QUV exposure, billboards printed with weather-resistant LED UV-curable ink showed a maximum color difference (△E) below 5. To the naked eye, this difference is barely noticeable.

.png)

Achieving long-lasting billboard colors requires high-grade lightfast pigments and proper substrate selection. Premium weather-resistant inks deliver superior cost efficiency through extended lifespan, while meeting modern sustainability standards.

Selecting professional-grade billboard ink is a strategic investment in brand value and environmental responsibility—ensuring every outdoor advertisement delivers maximum visual impact for years to come.